Planing

At MMS, we know that it's not just about reliable machines. Correct installation and professional handling are crucial for the best results in beverage filling. That's why we offer a range of services that are precisely tailored to your requirements.

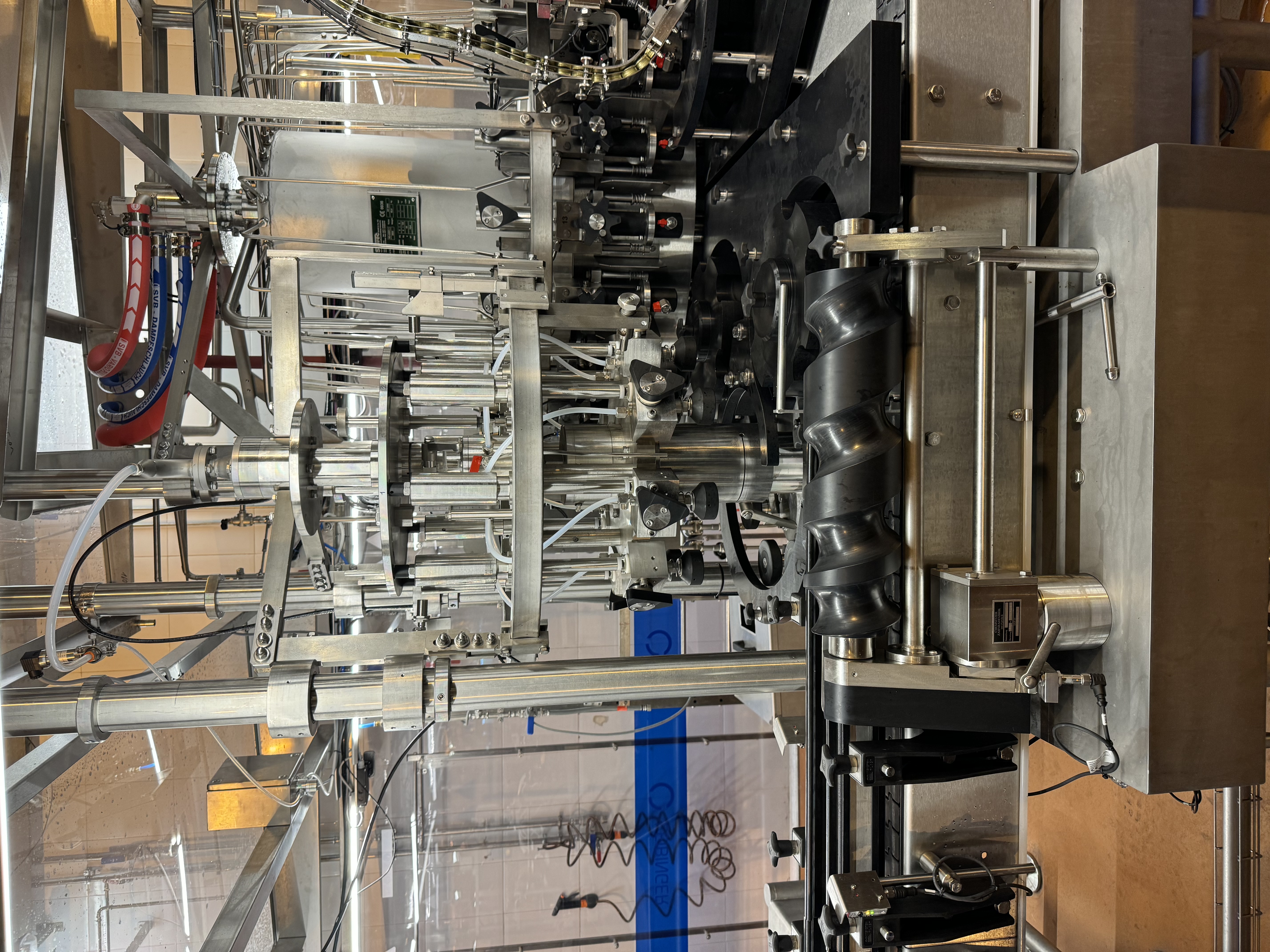

We install your new or used machines directly on site and commission them professionally.

Many problems can be solved remotely by our experts - this saves time and money, which is why we offer remote support.

We offer training courses that are tailored precisely to your needs - from basic foundation training to intensive technical instruction for machine operators and maintenance teams. This ensures that your staff are optimally trained and become real “filling specialists”.

Support and advice on adaptations to specific production requirements, such as switching to new bottle types or filling systems.